Features

Thermally broken fully glazed facade system with flush integrated full height sliding doors. In closed position inside and out flush with the adjacent areas, no misalignement of glass, no projecting extrusions.

Frameless glass appearance - all you see is glass, no change in material, homogeneous, seamless glass surface. Top hung sliding doors, effortless slide, no risk from dirt on the floor. Unique shear-proof edge seal with extreme rigidity, high resistance against wind and impact loads.

TESTS

- - Airtightness

- - Watertightness

- - Wind resistance

- - Impact resistance

OPENING STUDY

Our single leaf POP-IN can be fixed between 2 fixed glazed panels or next to a wall.

Our double leaf POP-IN is always fixed between 2 fixed glazed panels.

VERTICAL SECTION

The head profile is flush mounted with the ceiling which lets in the maximum possible amount of light. The bottom profile is flush mounted with the floor which allows for barrier-free living.

ELEMENT SIZES

The following maximum element sizes are possible:

- POP IN SLIDING DOOR: max. 250kg

- Fixed glazed panel: No restrictions in size and weight

THERMAL INSULATION

Less is more!

Thus our POP-IN is frameless, we safe material and you energy.

U values for a typical POP-IN facade with 2 POP-IN's and 4 fixed glazed panels (10,8m x 2,8m): Uw=1,3W/m²K

LOCKING

The multi-point locking mechanism of our POP-IN opens by turning the handle 90°. In closed position the handle is vertical and thus not visible form the outside.

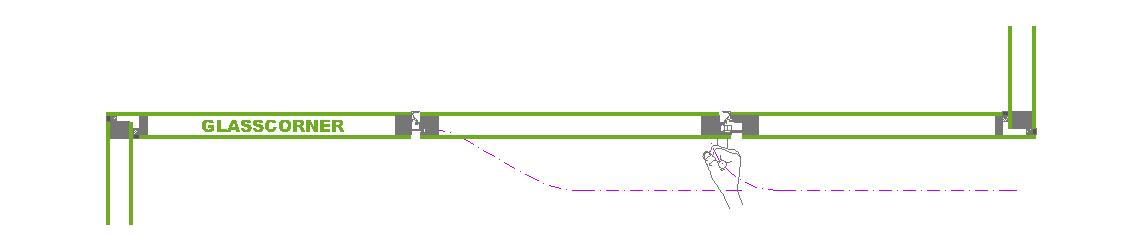

GLASS CORNERS

The glass corner integrates itself perfectly into the overall look of our POP-IN system.

SCREEN PRINTING

Screen printing opens up not only a range of glass design options limitless in their form, transparency and colour, but also new functions such as privacy, solar control and thermal regulation. Since the design is fired onto the glass surface, screen printed glass is resistant to scratching, abrasion, acid and light.